Neo Amity, Nanubhai Desai Road, Mumbai - 400004

Nickel Alloy Rings

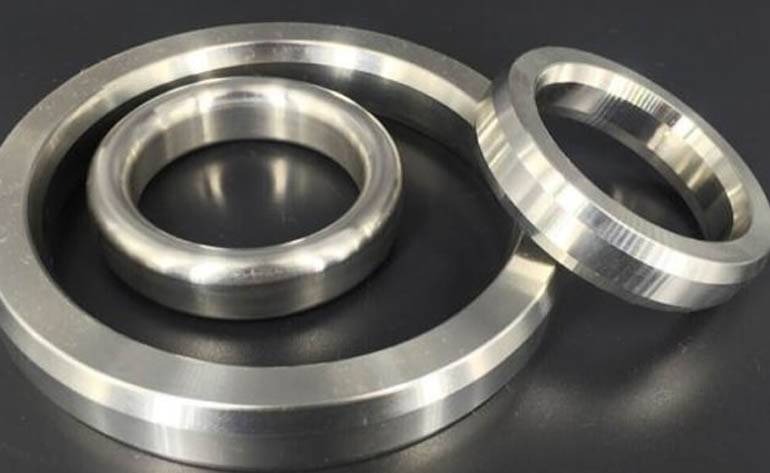

What is Nickel Alloy Rings?

Nickel alloy rings, particularly those produced by Metcore Alloys, are gaining recognition in various industrial applications due to their exceptional properties and versatility. These rings are crafted from nickel-based alloys that are known for their excellent corrosion resistance, high-temperature strength, and overall durability.

Nickel Alloy Rings, Nickel Alloy Rings Manufacturers, Nickel Alloy Rings Suppliers, Nickel Alloy Rings Stockists, Nickel Alloy Rings Exporters

As industries continue to seek materials that can withstand extreme conditions, the demand for nickel alloy rings is steadily increasing. This surge in popularity has led to a growing number of manufacturers, suppliers, stockists, and exporters specializing in these high-performance products.Metcore Alloys stands out as a reputable manufacturer in the field, utilizing advanced techniques and high-quality raw materials to produce nickel alloy rings that meet stringent industry standards.

The company's commitment to quality ensures that their products not only fulfill but often exceed customer expectations. With a focus on innovation, Metcore Alloys invests in research and development to enhance the performance characteristics of their nickel alloys, ensuring that their rings are suitable for a wide array of applications, including aerospace, chemical processing, oil and gas, and marine environments

Nickel Alloy Rings Manufacturers in India, Nickel Alloy Rings Suppliers in India, Nickel Alloy Rings Stockists in India, Nickel Alloy Rings Exporters in India

In addition to manufacturing, the role of suppliers and stockists is critical in making nickel alloy rings readily available to industries that require them. Suppliers play a vital role in sourcing high-quality materials from manufacturers like Metcore Alloys and distributing them to various sectors. Stockists, on the other hand, maintain significant inventories of nickel alloy rings to ensure immediate availability for customers.

This network of suppliers and stockists allows for quick turnaround times, which is essential in industries where downtime can result in significant financial losses.The market for nickel alloy rings is also bolstered by a number of exporters who facilitate the distribution of these products on a global scale. Exporters ensure that high-quality nickel alloy rings from manufacturers like Metcore Alloys reach international markets, catering to the needs of customers worldwide.

This global reach not only enhances the availability of nickel alloy rings but also fosters competitive pricing, as businesses can source materials from various suppliers across different regions.The unique properties of nickel alloys contribute to the growing interest among manufacturers and industries.Nickel alloy rings exhibit remarkable resistance to oxidation and scaling at elevated temperatures, making them ideal for high-heat applications.

Nickel Alloy Rings Manufacturers in Mumbai, Nickel Alloy Rings Suppliers in Mumbai, Nickel Alloy Rings Stockists in Mumbai, Nickel Alloy Rings Exporters in Mumbai

They also possess excellent mechanical properties, allowing them to maintain their strength and integrity even in challenging environments. This makes them a preferred choice for components such as valve seats, turbine blades, and heat exchangers. As the demand for nickel alloy rings continues to grow, the emphasis on quality and performance will remain paramount, driving further innovations in the manufacturing processes and the development of new alloy compositions.

Material Specification of Stainless Nickel Alloy Rings

| Specifications | ASTM A105 |

|---|---|

| Dimensions | ASTM, ASME, and API |

| Thickness | 15 mm to 400 mm |

| Size | 25 mm to 300 mm |

| Weight In Kg. | 1 Kg. to 300 Kg. |

| Grade | ASTM A516 gr 60/70 |

Equivalent Grades Of Nickel Alloy Rings

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

|---|---|---|---|---|---|---|---|

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | - | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

Chemical Equation of Nickel Alloy Rings

| GRADE | C | Mn | Si | S | Cu | Fe | Ni |

|---|---|---|---|---|---|---|---|

| Nickel 200 | 0.15 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

| Nickel 201 | 0.02 max | 0.35 max | 0.35 max | 0.01 max | 0.25 max | 0.40 max | 99.0 min |

Mechanical Composition of Nickel Alloy Rings

| ELEMENT | DENSITY | MELTING POINT | TENSILE STRENGTH | YIELD STRENGTH(0.2%Offset) | ELONGATION |

| Nickel 200 / 201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 67000 , MPa – 462 | Psi – 21500 , MPa – 148 | 45 % |

People Also Search

Nickel Alloy Rings, ASTM B162 Nickel 200 Rings, Nickel Alloy 2.4068 Rings, 201 Nickel Alloy HR Rings Manufacturer, Alloy 201 Rings, High Nickel Alloy 200 Cold Rolled Rings, Nickel Alloy 200 Rings, UNS N02200 Rings, Nickel Alloy Industrial Rings Supplier in Mumbai India, ASME SB162 200 Nickel Rings Stockist, High Nickel Alloy N02201 Flat Ring Gasket, Nickel 201 Forging Rings, Nickel 200 Proof Machined Rings, Alloy 201 Rolled Ring, Nickel 2.4066 Oval Ring Joint Gasket, Nickel 201 Die-Formed Ring Exporter in India, nickel 200 rings exporter, 201 nickel rings supplier in india, alloy n02200 ring sockist in mumbai, nickel 200 rings exporter in india, alloy 201 rings trader in mumbai, astm b162 200 nickel alloy rings, b162 nickel alloy 201 rings, alloy 2.4066 rings stockist in mumbai, nickel alloy n02201 rings price list, 201 nickel alloy rings specification, nickel 2.4066 / 2.4068 rings manufacturer, n02201 nickel alloy rings chemical composition, 2.4066 nickel rings supplier, nickel 200 rings price list, 26 gauge nickel alloy 2.4068 rings, n02200 nickel alloy rings sizes, 16 gauge alloy 200 octagonal ring joint gasket, nickel 2.4066 rings mechanical properties, nickel alloy n02200 rings thickness, 200 nickel rings gauge, nickel 201 rings gauge thickness chart, alloy 2.4066 rings cut to size, nickel alloy 200 rings dealer in india.

India

India Kuwait

Kuwait UAE

UAE UK

UK Italy

Italy China

China United States

United States Saudi Arabia

Saudi Arabia Malaysia

Malaysia Singapore

Singapore Germany

Germany Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Brazil

Brazil France

France Taiwan

Taiwan Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela