Neo Amity, Nanubhai Desai Road, Mumbai - 400004

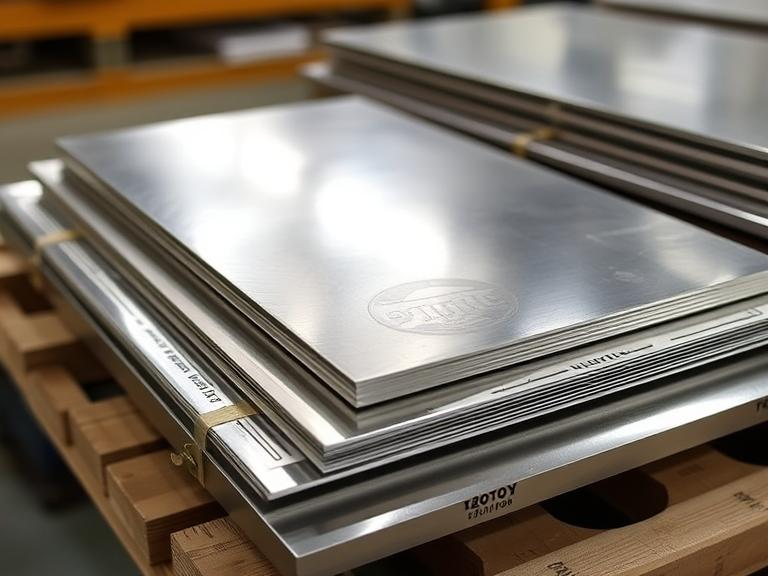

Inconel 625 Plates

Metcore Alloys is a consistent manufacturer, supplier, stockholder, and exporter of high-strength, corrosion-resistant, and high-temperature-resistant Inconel 625 plates. Nickel, chromium, and molybdenum are used to manufacture these plates. These plates are most appropriately utilized in applications requiring increased resistance to oxidation and aggressive environmental conditions. Aerospace, marine, chemical processing, and power generation sectors apply Inconel 625 plates owing to their performance and reliability in extreme operating conditions.

Inconel 625 Plates, Inconel 625 Plates Manufacturers, Inconel 625 Plates Suppliers, Inconel 625 Plates Stockists, Inconel 625 Plates Exporters

Inconel 625 plates have extensive applications in the aeronautics sector due to their fatigue strength and oxidation resistance. They are used extensively in jet engine components, heat exchangers, and exhaust ducts, where mechanical stress and high temperature are prevalent. With a leading manufacturer and supplier like Metcore Alloys, their aerospace-grade Inconel 625 plates meet tough industry specifications and deliver impeccable performance in extreme flying conditions.

Inconel 625 Plates Manufacturers in India, Inconel 625 Plates Suppliers in India, Inconel 625 Plates Stockists in India, Inconel 625 Plates Exporters in India

In marine and offshore processes, use of Inconel 625 plates is inevitable with their excellent performance against seawater pitting and corrosion. Submarine components, offshore oil rigs, heat exchangers, and seawater pipes extensively use these plates. As a consistent stockholder and exporter, Metcore Alloys provides Inconel 625 plates with stable performance in corrosive seawater environments with low life-cycle costs and greater efficiency.

Inconel 625 plates are highly resistant to heat and corrosion and are used in chemical processing and power generation industries. They are used in reactors, heat exchangers, boiler components, and flue gas scrubbers where corrosive chemicals and extreme temperatures are a standard. Metcore Alloys supplies Inconel 625 plates according to industry specifications to provide safety, reliability, and efficiency to chemical and power plants.

Inconel 625 Plates Manufacturers in Mumbai, Inconel 625 Plates Suppliers in Mumbai, Inconel 625 Plates Stockists in Mumbai, Inconel 625 Plates Exporters in Mumbai

Metcore Alloys is a well-established name in the industry, delivering high-quality Inconel 625 plates with precise size and excellent mechanical properties. As a manufacturer, supplier, stockholder, and exporter, timely delivery, the best price, and tailor-made to meet specific industrial use are guaranteed. For applications in aerospace, marine, chemical, or power industries, Metcore Alloys provides Inconel 625 plates with a guarantee to deliver high performance and durability in harsh environments.

Contact Metcore Alloys today to access high-grade Inconel 625 plates and experience the finest industrial solutions for your enterprise!

Material Specification of Inconel 625 Plates

| Specifications | ASTM / ASME SB 168, ASTM / ASME SB 424 , ASTM / ASME SB 443 |

|---|---|

| Standard | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 12 mm Thk |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Equivalent of Inconel 625 Plates

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb | ЭИ602 |

Chemical Equation of Inconel 625 Plates

| Grade | C | Mn | Si | P | S | Ni | Cr | Fe | Mo | Co | Al | Ti | Nb + Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 0.015 max | 58.0 min | 20.0 – 23.0 | 5.0 max | 8.0 – 10.0 | 1.0 max | 0.40 max | 0.40 max | 3.15 – 4.15 |

Mechanical Composition of Inconel 625 Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation | |

|---|---|---|---|---|---|

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

People Also Search

Inconel DIN 2.4856 Plates Manufacturer, Inconel 625 Hot Rolled Plates, Inconel Alloy 625 Chequered Plate, Inconel UNS N06625 Plates, 625 Inconel Alloy Perforated Plates, 625 Inconel Alloy Plates Supplier in India, ASTM B443 Inconel 625 Shim Plates, 625 Inconel Polished Cold Drawn Plates Manufacturer, 625 Alloy Plain Plates, Inconel 625 Hot Rolled Plates, Inconel Alloy 625 Plates Supplier In Worldwide, Inconel 625 werkstoff nr. 2.4856 Plates, Gr 625 Inconel Cold Rolled Plates, DIN 2.4856 Plain Plates, Inconel 625 Perforated Sheet Stockist, Inconel 625 Shim Sheet, ASTM B163 Inconel 625 Welded Plates, Inconel 625 Alloy Hot Rolled Plate, UNS N06625 Inconel 625 Chequered Plate, Inconel 625 Din 2.4856 Polished Plate Manufacturers in India

India

India Kuwait

Kuwait UAE

UAE UK

UK Italy

Italy China

China United States

United States Saudi Arabia

Saudi Arabia Malaysia

Malaysia Singapore

Singapore Germany

Germany Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Brazil

Brazil France

France Taiwan

Taiwan Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela