Neo Amity, Nanubhai Desai Road, Mumbai - 400004

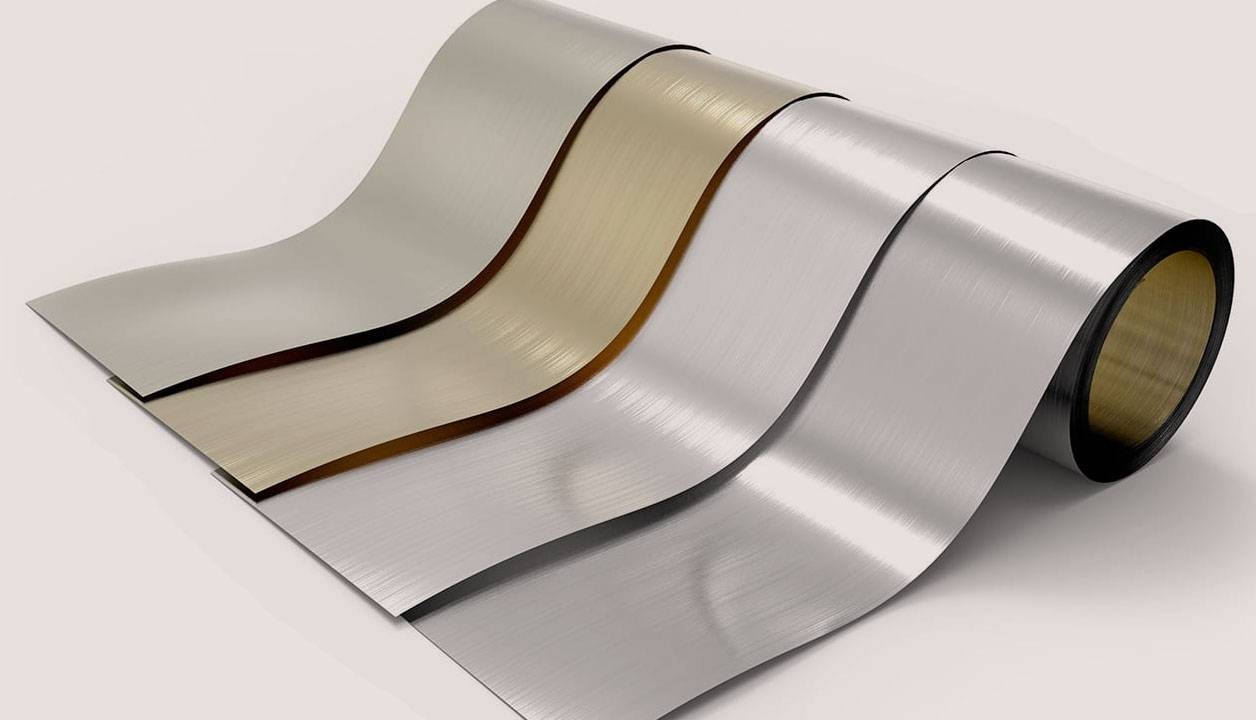

Hastelloy X Shims

Product Description: Hastelloy X Shims

Hastelloy X Shims Metcore Alloys are a premier performance alloy for extreme conditions. These shims offer exceptional resistance to oxidation and stress corrosion cracking in wide aerospace, chemical processing, and gas turbine applications. Metcore Alloys have exported Hastelloy X Shims to customers all over the world and deliver those items to the doorsteps of their customers.

Hastelloy X Shims, Hastelloy X Shims Manufacturers, Hastelloy X Shims Suppliers, Hastelloy X Shims Stockists, Hastelloy X Shims Exporters

They strictly follow quality and performance; therefore, they are very useful in critical applications. Hastelloy X is a nickel-based superalloy with very high strength and excellent oxidation resistance to 1200°C (2200°F). The unique chemical composition for this alloy enables the maintenance of mechanical properties under extreme temperature conditions; hence, it finds applications in situations where operation at elevated temperatures is required.

Hastelloy X Shims Manufacturers in India, Hastelloy X Shims Suppliers in India, Hastelloy X Shims Stockists in India, Hastelloy X Shims Exporters in India

Applications in furnace components, petrochemical processing, and aircraft engines benefit highly from the toughness and oxidizing capability of Hastelloy X Shims.Metcore Alloys specialize in the manufacture of Hastelloy X Shims of exacting dimensions and are hence capable of offering a wide range of thicknesses and sizes for different industrial applications.

Their expertise as manufacturers further enables them to extend customized shims since they adhere to the particular specifications of their clients for specific compatibility with various uses. These shims are manufactured in such a way that during extremely harsh service conditions, they remain intact and Buzz for long-term reliability.

This would include corrosion by uniform attack, stress corrosion, pitting and crevice corrosion, and intergranular corrosion. For one of the noted **suppliers**, Metcore Alloys, this pride is completely reflected in a range of products that are now more resistant to different forms of corrosion and are tough. The commitment of the company to excellence ensures that customers get products to international standards and certifications, making sure that performance is realized in the most demanding applications.

Hastelloy X Shims Manufacturers in Mumbai, Hastelloy X Shims Suppliers in Mumbai, Hastelloy X Shims Stockists in Mumbai, Hastelloy X Shims Exporters in Mumbai

From being manufacturers and suppliers, Metcore Alloys also acts as reliable stockists of Hastelloy X shims. They maintain a complete inventory in their stocks to meet the urgent requirements of their clients. Such huge stocks enable Metcore Alloys to assure speedy deliveries and satisfaction of immediate demands at small notice, especially on very important projects related to energy, power generation, and aerospace.

As renowned **exporters**, Metcore Alloys has acquired global recognition for exporting high-quality Hastelloy X Shims to clients across the world. Their close distribution network, along with timely shipment assurance, has helped in establishing faith among continental customers. Skill and experience regarding export regulations and logistics enable the company to deal with products without damage and well in time at any location in the world.

Material Specification of Hastelloy X Shims

| Specification | Details |

|---|---|

| ASTM | ASTM B 575, ASME SB 575 |

| Thickness | 0.02mm – 5.0mm |

| Shims Width | 3.2mm – 1500mm |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, Hairline, Scotch Brite, Satin Finish, NO.8, BA |

Equivalent of Hastelloy X Shims

| STANDARD | WERKSTOFF NR. | UNS | JIS |

|---|---|---|---|

| Hastelloy X | 2.4665 | N06002 | NW 6002 |

Chemical Equation of Hastelloy X Shims

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

|---|---|---|---|---|---|---|---|---|---|---|

| X | 0.010 max | 0.50 max | 0.08 max | 0.02 max | 2.50 max | 50.015 min* | 20.00 – 22.50 | 2.00 – 6.00 | 12.50 – 14.50 | 0.02 max |

Mechanical Composition of Hastelloy X Shims

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy X | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

People Also Search

Hastelloy Alloy X Plate, Hastelloy X Shim Sheet, ASME SB435 Hastelloy X Plate, Alloy X Sheets, Hastelloy Alloy X Plate Stockist, Hastelloy X Sheet, Hastelloy X Coil Suppliers, Hastelloy X Cold Rolled Plates, X Alloy Plate Exporter, ASTM B435 Hastelloy X Shim Sheets, Hastelloy X Sheets Dealer in India.

India

India Kuwait

Kuwait UAE

UAE UK

UK Italy

Italy China

China United States

United States Saudi Arabia

Saudi Arabia Malaysia

Malaysia Singapore

Singapore Germany

Germany Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Brazil

Brazil France

France Taiwan

Taiwan Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela