Neo Amity, Nanubhai Desai Road, Mumbai - 400004

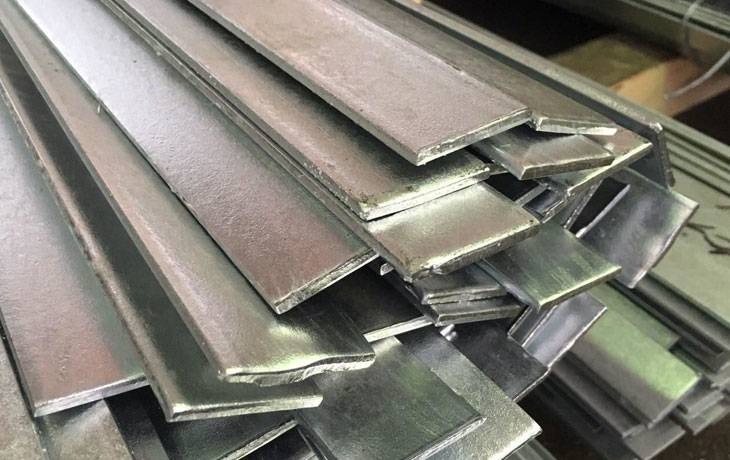

Duplex & Super Duplex Flats

What is Duplex & Super Duplex Flats?

Flanges made from duplex and super duplex are followed as an important element in various industries due to their unique compositions and topmost grade properties. Metcore Alloys is a well-recognized company for challenging manufacturing, supplying, stocking, and exporting interests of these special steels. Normally, the composition of a Duplex Stainless Steel is 22% chromium and 3% molybdenum. On the other hand, super duplex stainless steel contains 25% chromium, 3.5% molybdenum, and 0.22–0.3% nitrogen.

Duplex & Super Duplex Flats, Duplex & Super Duplex Flats Manufacturers, Duplex & Super Duplex Flats Suppliers, Duplex & Super Duplex Flats Stockists, Duplex & Super Duplex Flats Exporters

Their balanced microstructure, comprising of both ferrite and austenite phases, imparts the special characteristics that develop in duplex and super duplex stainless steels. In particular, this dual-phase structure gives to duplex stainless steel remarkable mechanical strength combined with superior resistance to corrosion.

Super duplex stainless steels, however, contain increased levels of chromium, molybdenum, and nitrogen; and, as a result, exhibit superior resistance against pitting and crevice corrosion, making this material suitable for an even more aggressive environment.

Duplex & Super Duplex Flats Manufacturers in India, Duplex & Super Duplex Flats Suppliers in India, Duplex & Super Duplex Flats Stockists in India, Duplex & Super Duplex Flats Exporters in India

Another critical factor is resistance to temperature, which is vital while choosing the right alloy for the task at hand. Operating conditions for Duplex Stainless Steel should, if possible, start from -40°C up to +280°C. Super Duplex Stainless Steel can operate within a wider temperature range, usually from -50°C to 300°, and this was the reason it can stand out well in very extreme conditions. The operating temperature range underlines wide applicability, extending from oil and gas to marine and chemical processing.

Applications involving duplex and super duplex stainless steels abound, showing a wide range of adaptability and reliability. Generally, the use of duplex stainless steel in construction and manufacturing is usually applied in less aggressive situations. Super duplex stainless steel is applied to those areas where applications are demanding, like in the oil and gas industries, since one of the big risks in those industries is corrosive exposure.

Working with super duplex stainless steel might have certain disadvantages. The high amount of alloying elements involved makes the fabrication and welding quite difficult compared to standard stainless steels. Therefore, manufacturing ability, stockists, and exporters need experience and equipment to deal with such materials efficiently and effectively. At Metcore Alloys, we pride ourselves on the capability to handle such issues and assure our clients that they will get nothing but high-quality products based on their needs and requests.

Duplex & Super Duplex Flats Manufacturers in Mumbai, Duplex & Super Duplex Flats Suppliers in Mumbai, Duplex & Super Duplex Flats Stockists in Mumbai, Duplex & Super Duplex Flats Exporters in Mumbai

The duplex and super duplex flats represent a quantum leap in the technology of stainless steel. Two different unique composition and property spectrums have distinguished these steel alloys. As a leading manufacturers, suppliers, stockists, and exporters of these valuable materials to industries all over the world, the companies like Metcore Alloys are very important.

Material Specification of Stainless Duplex & Super Duplex Flats

| Specifications | ASTM A240 / ASME SA240 |

|---|---|

| Dimensions | ASTM, ASME, and API |

| Size | 10 mm to 100 mm Dia in 100 mm to 6000 mm Length |

| Grade | UNS NO. S31803, S32205, S32550, S32750, S32760 |

Equivalent Grades Of Duplex & Super Duplex Flats

| STANDARD | UNS | WNR. |

|---|---|---|

| Duplex 2205 | S31803 / S32205 | 1.4462 |

| Super Duplex 2507 | S32750 / S32760 | 1.4410 |

Chemical Equation of Duplex & Super Duplex Flats

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Duplex S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| Duplex S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| Duplex S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| Duplex S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Composition of Duplex & Super Duplex Flats

| Element | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

|---|---|---|---|---|

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

People Also Search

S32760 Super Duplex HR Flats Manufacturer, UNS S32760, S31803 Cold Rolled Flats, Duplex / Super Duplex Steel Flats, ASTM A240 Duplex Steel S32205 Flats, Super Duplex Steel 1.4410 Flats, Duplex Steel 2205 Flats, Duplex / Super Duplex Industrial Flats Supplier in Mumbai India, duplex s31803 flats exporter, s32205 duplex steel flats supplier in india, super duplex s32750 flat stockist in mumbai, super duplex steel s32760 flats exporter in india, duplex 2205 flats trader in mumbai, astm a240 super duplex steel s32750 flats, a240 duplex steel 1.4462 flats, super duplex 2507 flats stockist in mumbai, super duplex s32760 flats price list, 1.4410 super duplex steel flats specification, duplex & super duplex steel 1.4462 / 1.4410 flats manufacturer, s32205 ferritic stainless steel flats chemical composition, 1.4462 duplex flats supplier, super duplex s32750 flats price list, 26 gauge super duplex stainless steel 1.4410 flats, s32750 super duplex flats sizes, 16 gauge duplex steel 1.4410 forging flat, 1.4462 duplex steel flats mechanical properties, super duplex s32760 flats thickness, s32205 duplex flats gauge, super duplex steel 1.4410 flats gauge thickness chart, duplex stainless steel 1.4462 flats cut to size, astm a240 duplex steel s32205 flats dealer in india.

India

India Kuwait

Kuwait UAE

UAE UK

UK Italy

Italy China

China United States

United States Saudi Arabia

Saudi Arabia Malaysia

Malaysia Singapore

Singapore Germany

Germany Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Brazil

Brazil France

France Taiwan

Taiwan Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela