Neo Amity, Nanubhai Desai Road, Mumbai - 400004

Duplex 2205 Plates

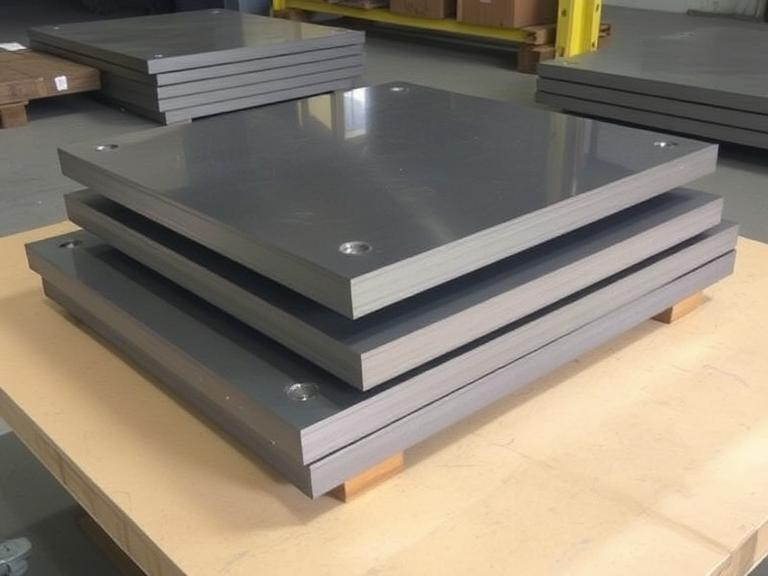

Metcore Alloys is a leading manufacturer, supplier, stockist, and exporter of high-strength Duplex 2205 plates, which are known for their high strength, durability, and resistance to corrosion. Duplex 2205 is a stainless steel enriched with nitrogen and has improved crevice corrosion, pitting, and stress corrosion cracking resistance than standard stainless steel. Duplex 2205 plates have extensive applications in industries where highly resistant and durable material is required to resist challenging environments.

Duplex 2205 Plates, Duplex 2205 Plates Manufacturers, Duplex 2205 Plates Suppliers, Duplex 2205 Plates Stockists, Duplex 2205 Plates Exporters

Duplex 2205 plates have extensive usage in offshore and onshore oil drilling operations owing to their excellent resistance to chloride-induced stress corrosion cracking. They are most appropriate for use in heat exchangers, pressure vessels, and pipelines in harsh operating conditions.

Duplex 2205 Plates Manufacturers in India, Duplex 2205 Plates Suppliers in India, Duplex 2205 Plates Stockists in India, Duplex 2205 Plates Exporters in India

Its resistance to corrosion is one reason Duplex 2205 is a material of preference for ship construction, marine hardware, and seawater applications. It resists deterioration and rusting in salt environments and can deliver prolonged performance and lifespan.

Duplex 2205 plates from Metcore Alloys are used in chemical processing plants where resistance to corrosive chemicals and high temperature is a requirement. These plates are used in storage tanks, reactors, and piping systems for corrosive material handling.

Duplex 2205 Plates Manufacturers in Mumbai, Duplex 2205 Plates Suppliers in Mumbai, Duplex 2205 Plates Stockists in Mumbai, Duplex 2205 Plates Exporters in Mumbai

Duplex 2205 Plates have wide applications in the pulp and paper industry, being used in digesters, bleach washers, and evaporators. Their ability to withstand acidic and alkaline environments makes them a reliable choice for this industry.

Due to their hygienic properties and acid and cleaner resistance, Duplex 2205 plates are used in food processing equipment, storage tanks, and milk processing plants. They are safe, clean, and durable for use in food processing. As a consistent manufacturer, supplier, stockist, and exporter, Metcore Alloys provides Duplex 2205 plates in varying sizes, thicknesses, and finishes to suit varied industrial requirements. With an emphasis on quality and customer satisfaction, we deliver products that work efficiently in tough environments. Contact us today for high-quality Duplex 2205 plates that suit international and industry-specific requirements.

Material Specification of Duplex 2205 Plates

| Specifications | ASME SA 240/ASTM A 240 |

|---|---|

| Material | Duplex 2205 |

| Standard Sizes | 1000 x 2000 mm, 1220 x 2440 mm, 1500 x 3000 mm, 2000 x 2000 mm, 2000 x 4000 mm |

| Width | 10-2500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sand, blast, Brush, etching, etc |

| SA-240 Duplex 2205 Plate & Sheet Thickness | 0.1mm to 100 mm Thk |

| Hardness | Quarter Hard, Half Hard,Spring Hard, Soft, Hard, Duplex 2205 Sheet suppliers |

| Stock available in form of | Shim Sheet, Rolls, Strip, Flats, Clad Plate, Plain Sheet, Plate, Sheet, Coils, Foils, Rolling Sheet, Rolling Plate, Flat Shim, Flat Sheet, Blank (Circle), soft annealed, sheared, annealed, tread plate,descaled, Checker Plate |

| Profiling | Plasma Plate Cutting Laser Plate Cutting Oxy-propane Flame Cutting |

| Plasma profiles | As per customer's drawings |

| Value added services | Plasma cutting, Waterjet cutting, Laser cutting, welding, edge preparation, etc. |

| Why choose Metcore Alloys? | The third party inspection is accepted. Mill Test Certificate is supplied with shipment. |

| Specialized in | ASTM A240 Type Duplex 2205 plate, sheet |

| Delivery time | 7-10 days if in stock. or it is 15-20 days depends to quantity. |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

Eqhivalent of Duplex 2205 Plates

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Duplex 2205/ S31803 | S31803 | 1.4462 |

Chemical Equation of Duplex 2205 Plates

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Duplex Steel S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22 – 23 | 3 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| Duplex Steel S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21 – 23 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Composition of Duplex 2205 Plates

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

People Also Search

Werkstoff Nr. 1.4462 Plate , Duplex 2205 Plate , Werkstoff Nr. 1.4462 Colled Rolled Plate, UNS S32205 Duplex Plate,Duplex Steel UNS S32205 Hot Rolled Plate, Duplex Steel 2205 Colled Rolled Plate, Duplex Steel 2205 Plate, ASTM A240 Duplex Steel 2205 Hot Rolled Plate, Alloy 2205 Hot Rolled Plate Supplier, Werkstoff Nr. 1.4462 Stockiest, Duplex Steel UNS S31803 Stockholder, Duplex Steel UNS S31803 Stockiest, Duplex Steel UNS S31803 Plate Stockiest, ASTM A240 Duplex Steel 2205 Hot Rolled Plate Exporter, Duplex Steel UNS S31803 Trader, Werkstoff Nr. 1.4462 Supplier, Duplex Steel Sheet, Duplex 2205 Plate, 2205 Duplex stainless steel sheet, UNS S31803 Plate, S32205 Sheet, ASTM A240 type 2205 Coil, ASME SA240 Grade 2205 Strip, Duplex 2205 Sheet, UNS S31803 Foil, ASTM A240 type 2205 Sheet

India

India Kuwait

Kuwait UAE

UAE UK

UK Italy

Italy China

China United States

United States Saudi Arabia

Saudi Arabia Malaysia

Malaysia Singapore

Singapore Germany

Germany Canada

Canada Iran

Iran Thailand

Thailand South Korea

South Korea Turkey

Turkey Morocco

Morocco Costa Rica

Costa Rica Kazakhstan

Kazakhstan Philippines

Philippines Egypt

Egypt Japan

Japan Russia

Russia Vietnam

Vietnam Australia

Australia Qatar

Qatar South Africa

South Africa Portugal

Portugal Oman

Oman Jordan

Jordan Spain

Spain Hong Kong

Hong Kong Brazil

Brazil France

France Taiwan

Taiwan Netherlands

Netherlands Indonesia

Indonesia Mexico

Mexico Nigeria

Nigeria Bangladesh

Bangladesh Iraq

Iraq Ukraine

Ukraine Poland

Poland Romania

Romania Cyprus

Cyprus Angola

Angola Colombia

Colombia Norway

Norway Chile

Chile Tobago

Tobago Greece

Greece Czechia

Czechia Belgium

Belgium Sri Lanka

Sri Lanka Myanmar

Myanmar Venezuela

Venezuela